More stealthing...

The boys then cracked out the trusty Dremel again to cut a hole for the IDE cables to neatly pass through. This was filed and then test fitted with a couple of IDE cables.

They must have had something against this poor piece of metal, because it was starting to look like a piece of Swiss cheese. Following on, another hole was cut for the power supply fan to ensure the power supply gets enough ventilation. First of all, this was filed down with a Dremel grinding bit before they resorted to using a hand file for the finishing touches.

Sanding sealer was then spread over the welded joints. This fills in all of the small holes you end up with after welding and allowed them to get a smooth finish on the join before they started painting.

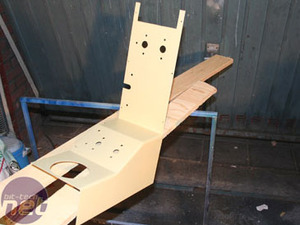

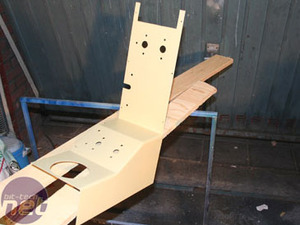

Before they started applying the final coat, the piece was given a thick coat of primer. Because the primer comes out in a creamy colour, the piece now

did look like Swiss cheese (

maybe I should eat something... I can't seem to stop the food references - Ed). Once the top coat had dried, the piece was test fitted - it fits perfectly!!

Want to comment? Please log in.